With the rapid development of the economy, cars have become an indispensable means of transportation for people, and more and more people will own cars. However, with the attendant problems of environment and energy, transportation not only provides convenience for people, but also becomes one of the main causes of environmental pollution. Automobile is a pillar industry and a basic means of transportation. Governments all over the world strive to promote economic development and improve people's living standards with the development of automobile. The use of new energy vehicles can reduce oil consumption and protect the atmosphere while maintaining the growth of automobiles.

New energy vehicles are the intersection of high-tech and sustainable development mode, the highlight of energy saving, emission reduction and low-carbon economy, and the focus of the development of a new generation of automobile industry. Modern electric vehicles fall into three categories: pure electric vehicles, hybrid electric vehicles and fuel cell electric vehicles.

Compared with traditional cars, the characteristics of new energy vehicles are particularly obvious:

(1) High energy conversion efficiency. The energy conversion efficiency of fuel cells can be as high as 60 ~ 80%, which is 2 ~ 3 times that of internal combustion engines.

(2) Zero emission, no environmental pollution. Fuel cell fuel is hydrogen and oxygen, the product is clean water;

(3) Hydrogen fuel is widely available, can be obtained from renewable energy sources, and does not rely on petroleum fuels.

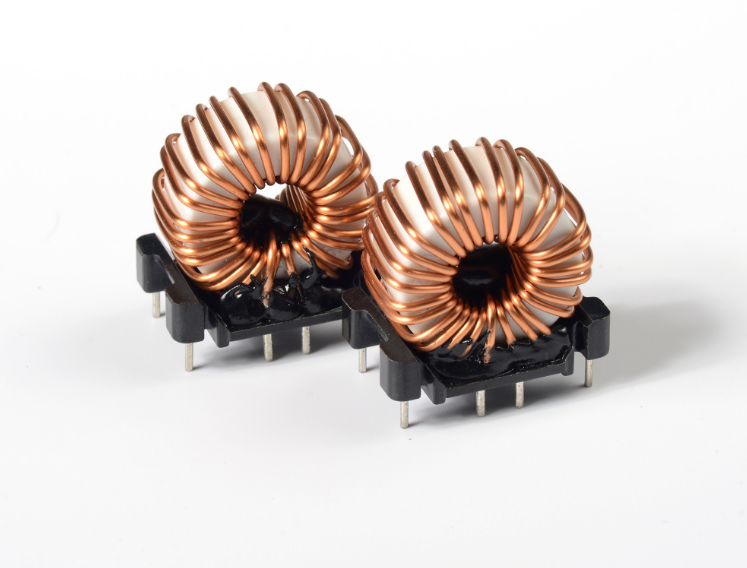

New energy inductors are widely used in automotive electronic circuits and are important components of automotive electronic technology. According to the function is divided into two categories, the first, the body electronic control system, such as: sensors, DC/DC converter; Second, vehicle electronic control system, such as: vehicle CD/DVD audio system, GPS navigation system, etc. New energy inductance solutions are developing in the direction of high efficiency, small size and low noise, giving full play to the advantages of new energy vehicles.

The magnetic core is mainly used in the 3 parts of automotive electronic soft magnetic components: the new energy inductor mainly plays the role of filtering, oscillation, delay, trap and so on in the circuit, as well as screening signals, filtering noise, stabilizing current and inhibiting electromagnetic wave interference. DC/DC converter is a kind of power conversion equipment of DC power supply, and the BOOST DC/DC converter used by new energy vehicles is mainly used for boosting the high voltage system to meet the operation of the motor drive system.

We know that the new energy vehicle charging pile is a large power supply, it is the conversion of AC to DC high voltage, in addition to the new energy vehicle core components including power battery packs, traction motors and generators, power electronics and other in a complex physical environment, but also to solve the electromagnetic compatibility/electromagnetic interference between the electromagnetic components of the system integration. Otherwise, electromagnetic interference will affect the normal operation of the motor. Ferrosilicon magnetic powder core has the advantages of high magnetic flux density (BS) and small size. When the main circuit current is large, the inductor will appear DC bias, resulting in magnetic circuit saturation. The greater the current, the greater the saturation degree of the magnetic circuit. Therefore, iron-silicon magnetic powder core is chosen as the magnetic core material.

Ferrosilicon magnetic core is widely used, and distributed air gaps are formed inside it. When magnetized, these distributed air gaps can store considerable energy. It has the advantages of good inductance linearity, low loss, small size, uniform temperature distribution, good insulation strength, high mechanical strength and low noise. Magnetic powder core is the key component of high frequency, high current, high power inductor devices, but also applied to the core components of new energy vehicles (battery, motor, electric control), metal magnetic powder core has a good resistance to external stress characteristics, so that the new energy vehicle drive motor has higher reliability, high power density, no noise, long service life and other characteristics.

New energy vehicles are used in high-voltage and high-current high-power electronic conversion devices and drive motors, and there are many electronic and electrical equipment on the car, and the electromagnetic sensitivity of the equipment is also different, and the entire vehicle is in a very complex electromagnetic environment. Therefore, in new energy vehicles, electromagnetic compatibility between various electrical components has become an important issue.

The above content is the introduction of the role of inductors in new energy vehicles.Dezhou Sanhe Electric Co., Ltd. takes a leading position in the field of inductance solutions for new energy vehicles, providing high-quality and efficient iron-silicon powder cores. Our products contribute to the overall system optimization, electromagnetic compatibility and enhanced performance of new energy vehicles. If you need inductors or other electronic components, we welcome you to contact us for more information and consultation.

Post time: Jul-09-2023